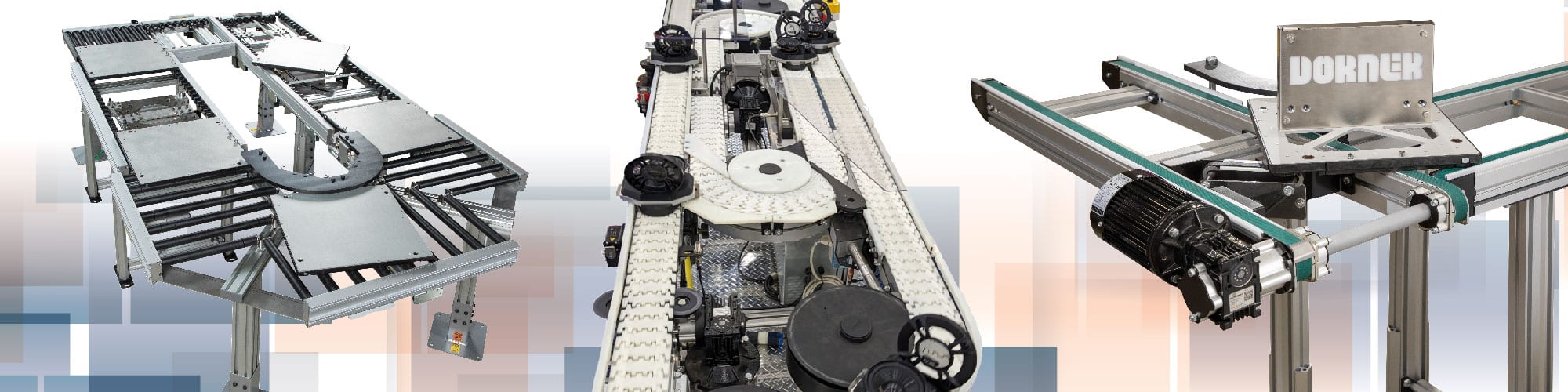

Dorner Pallet Systems

Features & Benefits

Dorner’s Pallet System conveyors simplify product flow and control with features such as a unique pin tracking system, industry-compatible pallet sizes, and innovative modules. All of our pallet system conveyors are modular and easy to customize to fit almost any application.

We offer a variety of pallet systems including timing belt, flexible chain, and edge roller technology designs. Each system offers advanced pallet traffic management and is specifically designed to increase efficiency, reduce downtime in automation processes, and provide accurate product placement.

Features

- Our most accurate product placement and positioning conveyors

- Industry-leading product routing and control

- Integration with robotics and automated processes

- Low-profile design

- Wide variety of modules for easy customization

- Customizable pallet size options available

Benefits

- Our most accurate product placement and positioning conveyors

- Industry-leading product routing and control

- Integration with robotics and automated processes

- Low-profile design

- Wide variety of modules for easy customization

- Customizable pallet size options available

Pallet System Product Lines

Dual timing belt conveyor system offers highly accurate product positioning within ± 0.5 mm, and is perfect for automated production operations.

Utilizing edge roller technology (ERT), the clean, open-frame design is ideal for electronics assembly, pharmaceutical processing, and more.

Flexible chain pallet system is a highly customizable solution for lightweight product assembly, routing, and inspection.

Industries & Applications

Pallet conveyor systems offer a unique solution for numerous applications, such as automated manufacturing, inspection and testing, product routing and flow, and robotics integration. Dorner’s pallet systems are designed to be highly customizable and easily reconfigured in the field, meaning this investment can grow and adapt to your operation.

Pallet systems are ideal for:

- Automated manufacturing

- Electronics assembly

- Medical device manufacturing

- Cleanroom applications

- Machine integration

- Material handling

- Packaging

- Pharmaceuticals