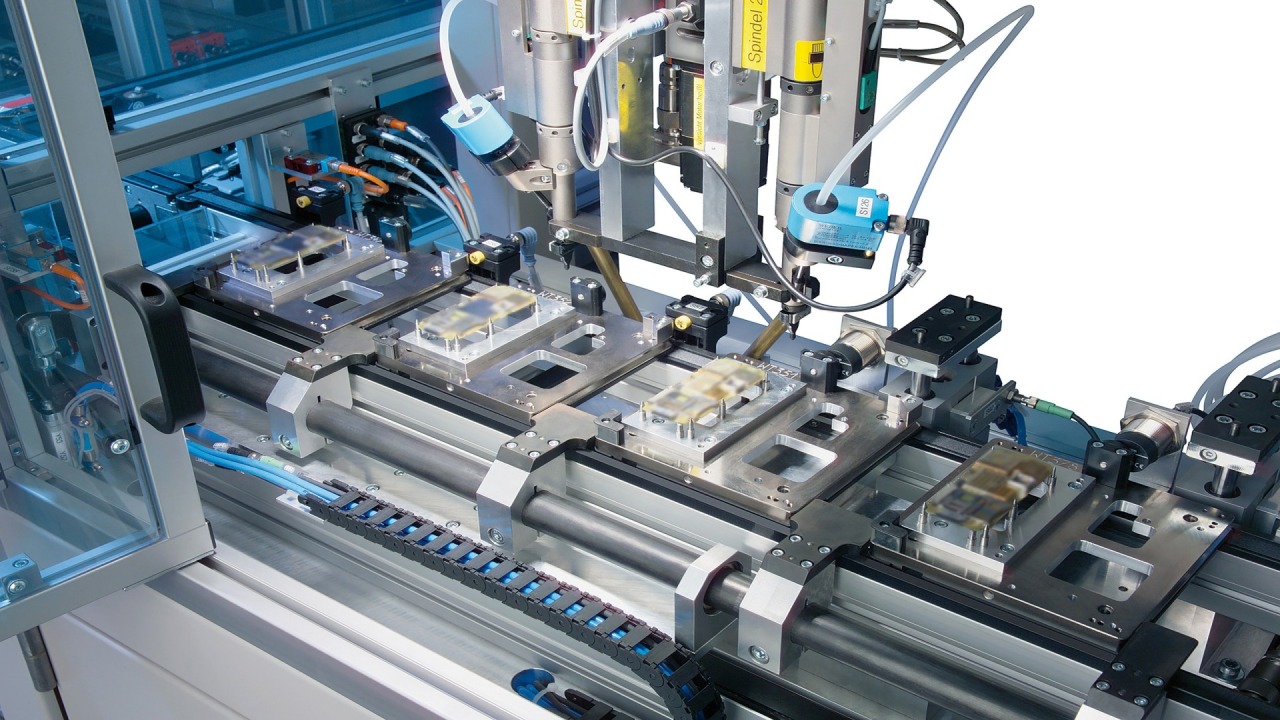

TS 1 transfer system – tailored to assemble small products

When it comes to the efficient production of small products or modules, the Rexroth TS 1 conveyor system is the right decision. It is specially tailored to the precise assembly of complex products. The ability to integrate into the pre-assembly and subassembly of a higher-level system is one of its strengths.

How to Choose the Right Conveyor System for Your Assembly Operation

Whether the product being manufactured is a mobile phone or an aircraft seat, the assembly processes will likely require some combination of manual and automated transfer operations. Read the article for some expert insights on choosing the right conveyor for the job!

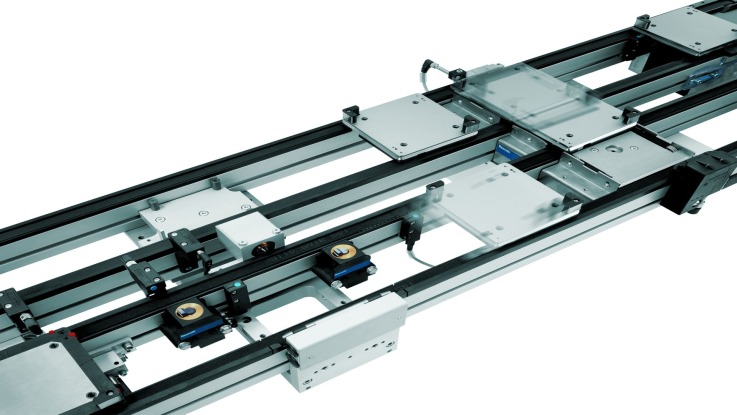

TS 1 Features at a glance

Holistic

A complete series of pallet based transfer, positioning, and control modules satisfies all requirements of manual and automated assembly operations, and allows the configuration flexibility required in today's competitive manufacturing environment.

Special components

TS 1 anti-static pallets protect delicate components better than other conveyor systems while allowing access to the workpiece from any direction. Light-weight plastic pallets are available for inspection or light assembly processes, while rugged steel pallets provide a solution for applications which require more precision.

| Workpiece pallet weight: |

up to 3 kg |

| Workpiece pallet sizes: | 80 x 80 mm, 120 x 120 mm, 160 x 160 mm |

| Workpiece pallet varieties: | plastic, plastic/steel and aluminum |

| Conveyor media: | belt, toothed belt |

| Conveyor speed: | 6, 9, 12, 15, 18 m/min |

| High repeat accuracy: | of ± 0.015 mm |

| Suitable for: | Class 6 cleanrooms (EN ISO 14644-1), dry rooms (up to approx. 1% relative humidity) |

| Special components: | accumulation curves for short throughput times, positioning unit for top repeat accuracy and quick workpiece pallet changeover |