Transferring your heavy products with minimal maintenance: that moves us.

BOOST YOUR PRODUCTION with the TS 5 transfer system.

The heavy weight in the Rexroth product transfer system line shines thanks to its tremendous cost-effectiveness and consistent quality. With its king shaft drive, the TS 5 stands out as a rugged pacemaker even in the harshest manufacturing environments – and the greatest possible degrees of freedom for you when it comes to layout planning and use of space. The TS5 roller conveyor can be adjusted even more flexibly to the requirements of the most diverse industries – from the automotive industry, to electro mobility and electronic and household devices. The elite class of roller conveyors offers an efficient and economical solution for every application.

How to Choose the Right Conveyor System for Your Assembly Operation

Whether the product being manufactured is a mobile phone or an aircraft seat, the assembly processes will likely require some combination of manual and automated transfer operations. Read the article for some expert insights on choosing the right conveyor for the job!

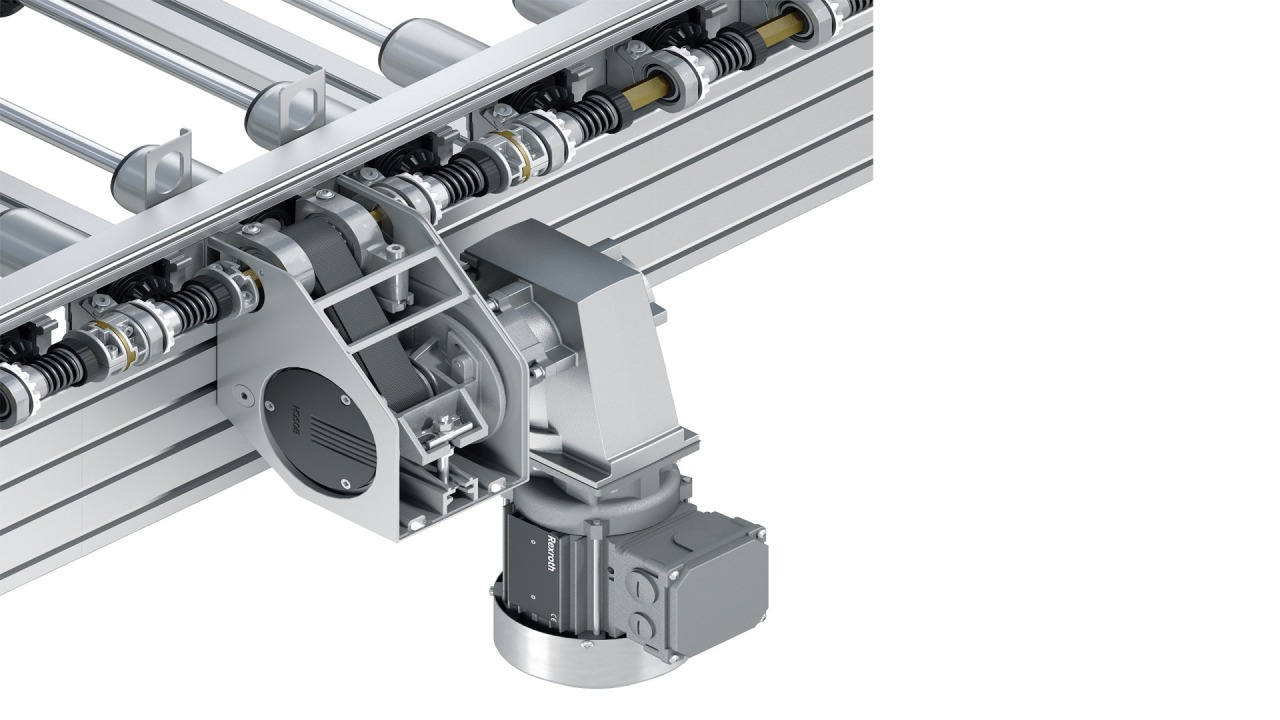

The TS 5 transfer system with king shaft offers considerable advantages compared to usual chain drives.

For example:

- Low maintenance

- Noise-free operation

- High energy efficiency through effective performance with low drive force requirements

TS 5 Features at a glance

Simple design

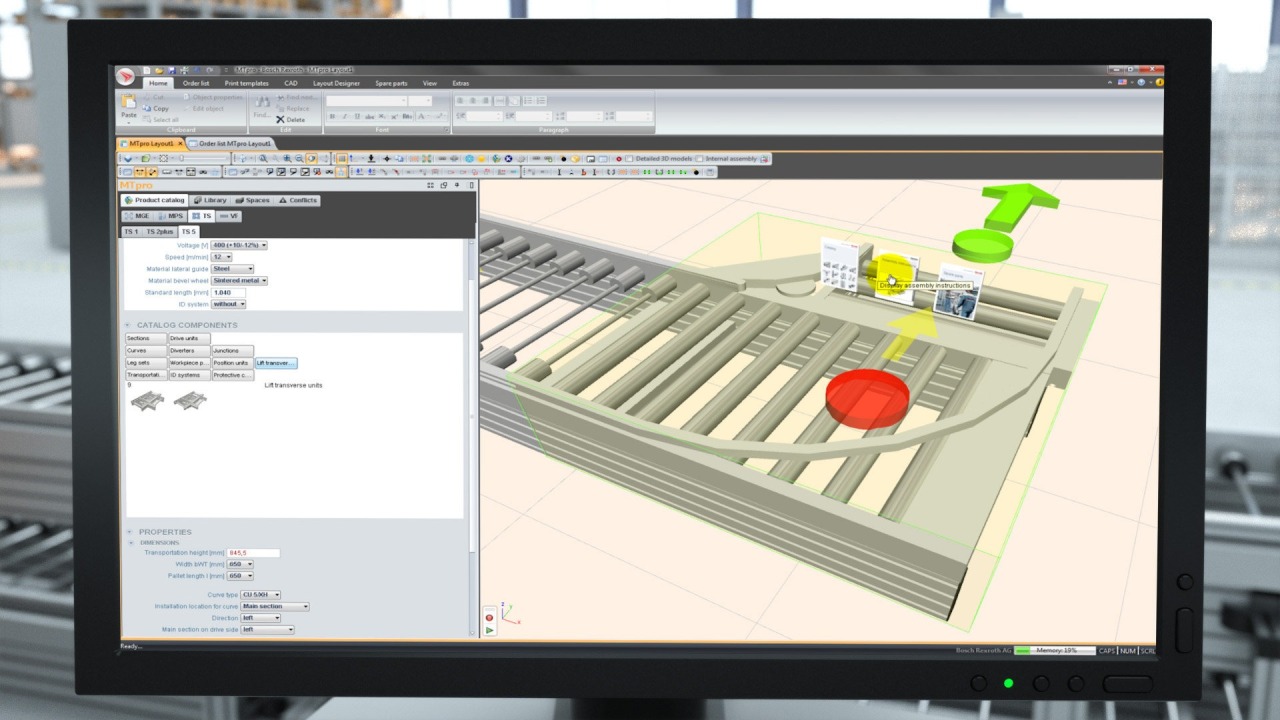

Thanks to the clever combination of the customer-friendly MTpro CAD program and the intelligent design of the components, the system can be customized according to your wishes. The MTpro is a proven, excellent tool which enables planning that is both application-oriented and fast. This significantly shortens the planning process and ultimately saves time and money in the procurement process. Automated order lists and links to the product catalog and installation instructions further simplify the entire project planning process.

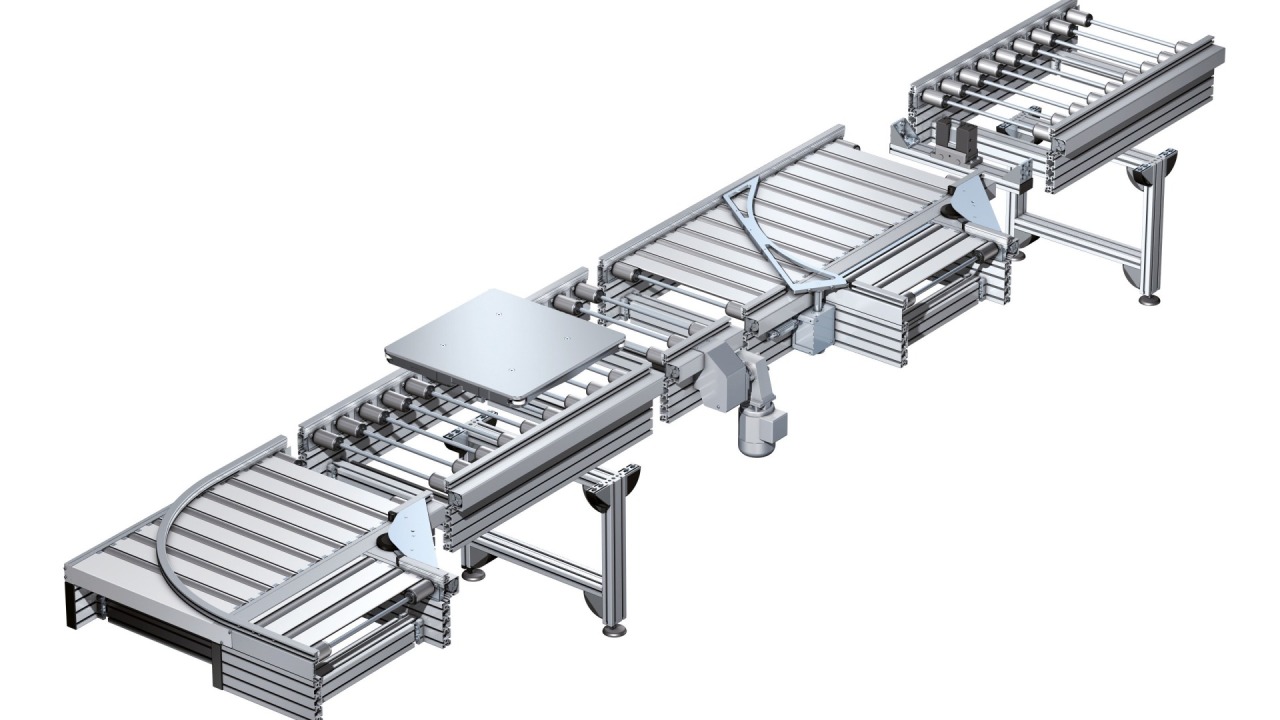

Modular construction

TS 5’s modular design principle makes a variety of layouts possible. As a result, changing or expanding the transfer system couldn’t be easier. Enhanced with numerous modules that offer a high degree of customizing possibilities and a thoughtful modular design principle, the innovative transfer system offers you more freedom than ever in system design and construction.

Reliable system

The TS 5 is an extremely reliable system with the highest degree of quality. The king shaft drive offers a long service life requiring minimum maintenance. In contrast to a chain-driven conveyor, the TS 5 with king shaft installation can be used without any limitations. You can, for example, branch the system off to the right or to the left. This is very economical because no additional drive modules are needed in many system layouts.

Efficient concept

When it comes to intelligent solutions, the efficient concept of the TS 5 is simply unbeatable. Whether your focus is total cost of ownership or better energy efficiency, TS 5 is head and shoulders above the rest. With a system width ranging from 455 to 1040 mm and the ability to freely choose the length of the roller section, it’s easy to select and implement the exact you need.

| Workpiece pallet weight: |

> 400 kg, max. 50 kg per roller |

| Workpiece pallet sizes: | 455 x 455 up to 1,040 x 845 mm |

| Roller dimension: | 60 mm |

| Roller spacing: | 130, 195, 260, 325 mm |

| Environments: | Approved for Class 8 cleanrooms in accordance with DIN EN ISO 14644-1 |

| King shaft drive: |

Low-maintenance, energy-efficient and low noise drive concept |

| "Open Center": | Open conveyor section for easy access to the workpiece from below |

| Three-way diverter: | T-shaped outfeed with three options: right, left, up or down |

| Rotation unit: | Performs the function of a diverter, junction and crossing in one unit, rotation angle from 45° up to 180° |

| Positioning unit: | Absolute precision (+/- 0.3 mm) through accurate positioning of workpieces at processing stations |

| Drive unit: | Powerful drive unit incl. conveyor section with flexible configuration options |

| Lift transverse unit: | Easy to transport workpieces in the transverse section with a stroke of 4.5 mm |

| Drive kit: | Drive kit as separate, self-contained module with conveyor section which can be placed at the beginning or end face of the conveyor |

| Swing gate: | Mobile swing gate for flexible access in a square |