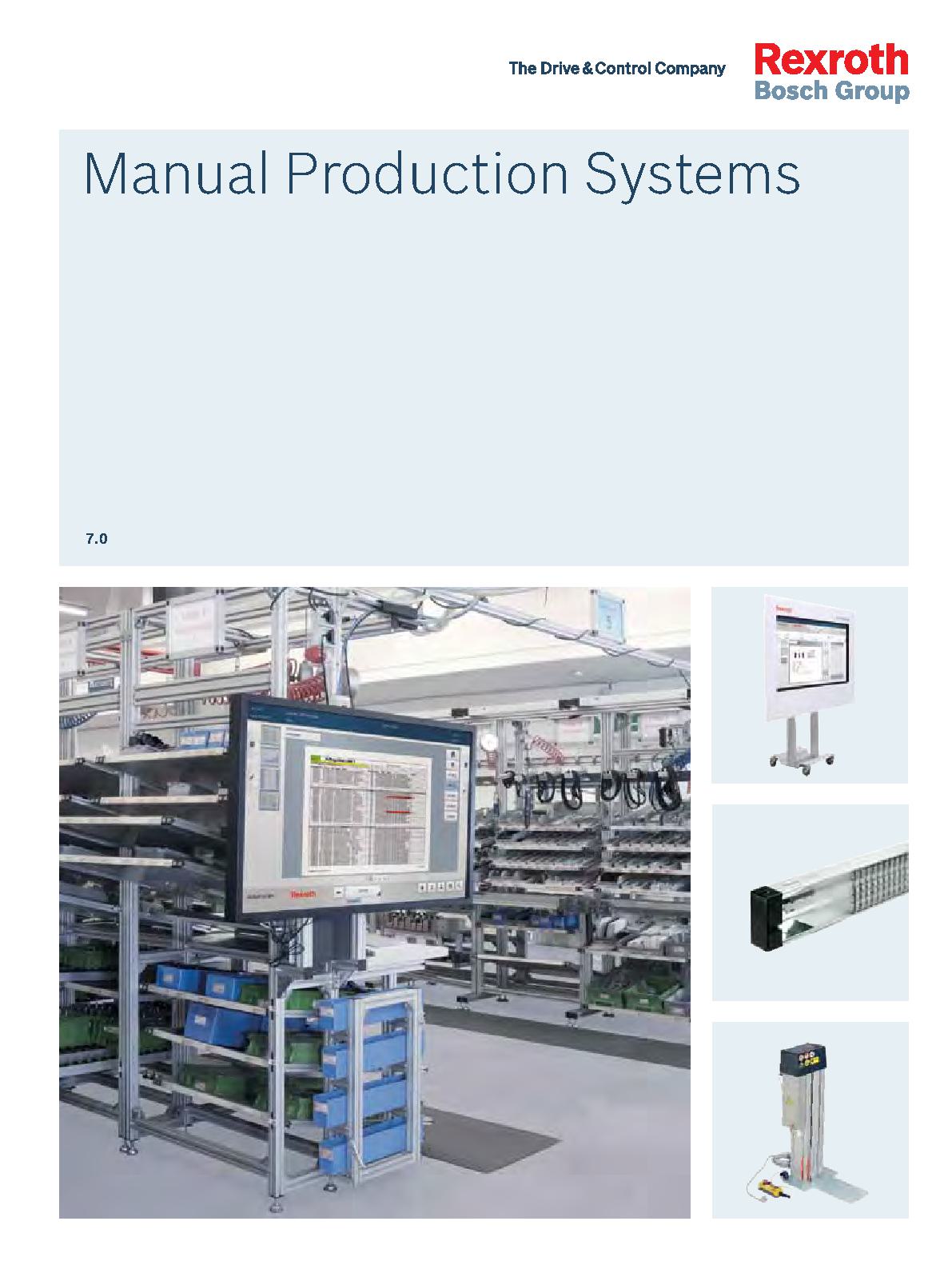

MATERIAL SHUTTLE ARBEITSPLATZ

| Conductivity [ESD] | yes, no |

| Material shelf depth max [TE max] | 1220mm |

| Material shelf depth min [TE] | 410mm |

| Material shelf material [M] | 3 different surface materials |

| Material shelf width max [BE] | 1480mm |

| Material shelf width min [BE] | 250mm |

| Material shuttle height max [H max] | 2200mm |

| Material shuttle height min [H min] | 600mm |

| Number of material shelves [NM] | 0 ... 4 |

| Packaging unit | 1 |

| Profile slot | 10 |

| Required accessories | Rubber profile to protect against heavy impacts when positioning the material shuttle,Swivel fastening for tilting the material shelf |

| Type of information board [Ityp] | 7 different information boards |

| Version [A] | Disassembled, assembled |

| Weight | 0kg |

| Work surface height max [H1A] | 1500mm |

| Work surface height min [H1A] | 410mm |

- Parts positioned within grab area of workstation

- Short conversion times with quick exchange of precommissioned material shuttles

- Can be equipped and sized to meet specific requirements

- Available as ESD-conductive version

- Design: Fully assembled or as a kit for self-assembly

- Optional information board for supplying information directly at location

- Adjustable material shelf height, offset, and tilt to ensure ergonomic grabbing

- Material shelves Basic including lettering clip; selection of various plates

- LR: Ball bearing, with locking mechanism locking device

- Can be used in combination with workstation or for supplying materials in conjunction with the manual linking system EcoFlow

- 1 - Parts positioned within grab area of workstation

- 2 - Short conversion times with quick exchange of precommissioned material shuttles

- 3 - Can be equipped and sized to meet specific requirements

- 4 - Available as ESD-conductive version

- 5 - Design: Fully assembled or as a kit for self-assembly

- 6 - Optional information board for supplying information directly at location

- 7 - Adjustable material shelf height, offset, and tilt to ensure ergonomic grabbing

- 8 - Material shelves Basic including lettering clip; selection of various plates

- 9 - LR: Ball bearing, with locking mechanism locking device

- 10 - Can be used in combination with workstation or for supplying materials in conjunction with the manual linking system EcoFlow

Design: Fully assembled or as a kit for self assembly, Parts positioned within grab area of workstation, Short conversion times with quick exchange of precommissioned material shuttles, Can be equipped and sized to meet specific requirements, Optional inf

Rubber profile

Rubber profile

To avoid hard abutting edges, for instance when setting down impact-sensitive products As a footrest: Clip in from top and front on the cross strut of the workstationCAD data

Lettering clips

Lettering clips

For labeling material shelves Suitable for labeling all profiles with 8 mm or 10 mm slotCAD data

Max. material shelf loads

|

TE (mm) |

1220 |

1220 |

840 |

765 |

1000 |

1000 |

840 |

765 |

|

|

BE (mm) |

1480 |

840 |

1480 |

840 |

1000 |

840 |

1000 |

840 |

|

|

Plate: aluminum |

FB1) (N) |

700 |

700 |

700 |

1000 |

||||

|

Plate: PP, SB |

FB1) (N) |

250 |

280 |

280 |

360 |

| 1) | FB is a distributed load and must not occur as a point load. |

|

Design |

Max. total weight of workstation material shuttle |

Max. total weight of material shuttle Logistics |

|

|

|

|

Normal |

4200 N |

4200 N |

|

ESD |

4000 N |

4000 N |

Request Quote

How to Find Us

If you have any questions, just fill in the contact form, and we will answer you shortly. If you are living nearby, come visit us.